Metrology and Inspection

At Cairnhill, we provide comprehensive inspection, quality assurance, metrology, and engineering consultancy services designed to meet the evolving needs of the manufacturing industry. Our expertise ensures that products, components, and processes adhere to the highest standards of precision, compliance, and reliability.

With a team of highly qualified professionals holding internationally recognized certifications, we bring extensive industry knowledge and cutting-edge techniques to every project. Our advanced metrology solutions enhance accuracy in measurements, helping manufacturers maintain consistency, optimize performance, and reduce defects. By integrating state-of-the-art technology and best practices, we support businesses in achieving operational excellence, regulatory compliance, and long-term success in an increasingly competitive market.

1000

Data Points Per Second

0.8

Microns Per Meter Accuracy

Dimensional Verification & Metrology Services

Ensuring that components meet exact specifications is crucial for maintaining quality, functionality, and compliance in manufacturing and engineering applications. Our dimensional verification and metrology services use state-of-the-art measurement technologies to provide highly accurate assessments, ensuring that parts conform to design tolerances, industry standards, and customer requirements.

- Geometric dimensioning & tolerancing (GD&T) assessments

- Component validation for manufacturing accuracy Using state-of-the-art FARO equipment, we deliver highly accurate surveying and reverse engineering solutions, including:

- FARO Focus 3D Scanner: High-resolution 3D scanning for detailed spatial analysis up to 350m per scan.

- FARO Vantage Laser Tracker: Precision measurement for large-scale components.

- FARO CMM Arm: Advanced coordinate measuring technology for detailed inspections of smaller components.

- FARO RevEng & CAM2 Spatial Analysis Software: Engineering software which can create and edit high-quality meshes and CAD surfaces from 3D point clouds for reverse-engineering workflows.

- Lecia Total Station: Leica FlexLine is a manual total station, enabling us to carry out accurate surveys and stakeout tasks easily and efficiently.

Surveying & Reverse Engineering

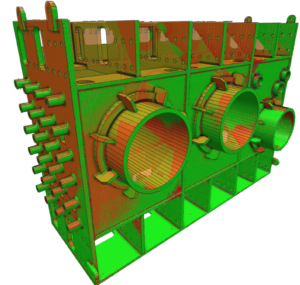

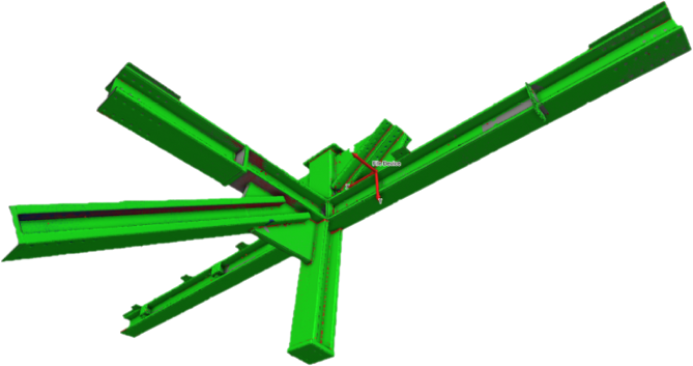

Reverse engineering in the steel construction industry allows engineers to analyze existing structures, components, or machinery to understand their design, material properties, and performance characteristics. By scanning or modeling an existing steel structure, professionals can create detailed blueprints, identify potential flaws, and improve upon original designs. This process is particularly useful for retrofitting aging infrastructure, replicating outdated or undocumented components, and optimizing fabrication techniques. Additionally, reverse engineering enables engineers to ensure compliance with modern safety and efficiency standards while reducing costs by eliminating the need for entirely new designs.

Non-Destructive Testing

We offer a full suite of On-Call Non-Destructive Testing (NDT) services, utilizing cutting-edge techniques to detect flaws and defects without compromising the integrity of materials.

Our Inspection services include:

- Ultrasonic Testing (UT): High-frequency sound waves to detect internal flaws.

- Phased Array Ultrasonic Testing (PAUT): Advanced UT technique for detailed defect imaging.

- Magnetic Particle Inspection (MPI): Effective for detecting surface and near-surface discontinuities in ferromagnetic materials.

- Dye Penetrant Inspection (DPI): A cost-effective method for identifying surface cracks.

- Eddy Current Testing (ECT): Ideal for detecting surface and subsurface defects in conductive materials.

- Drone Inspection – Visual inspection of high rise locations with restricted access.Our certified ICorr Corrosion Inspectors specialize in corrosion prevention and coating integrity assessments, ensuring long-term protection against environmental and operational damage.

- Verification of surface preparation, coating application, and curing processes

- Inspection during manufacture or in service surveying of protective coatings, linings, and cathodic protection systems

- Compliance assessments based on international standards (ISO, NACE, ASTM, SSPC)

Key Assets

FARO Focus 3D

- FARO Focus 3D Scanner delivers high-precision laser scanning for accurate measurement and documentation. Its fast data capture reduces manual effort while enhancing quality control. With millimeter-level accuracy and versatile portability, it streamlines inspections, minimizes errors, and improves efficiency across various industries.

FARO Vantage Laser Tracker - The FARO Vantage Laser Tracker enables high-precision measurement for large-scale projects, ensuring accuracy in alignment, calibration, and inspection. Its advanced technology enhances efficiency, reduces errors, and improves quality control.FARO CMM Arms

- The Quantum Scan Arm boasts impressive specifications, including accuracy levels of up to ±0.018mm (0.0007 in) and a volumetric accuracy of up to ±0.064 mm/m (0.0008 in/ft)

Quality Assurance & Welding Inspection

Our expert Engineering Consultants hold IIW, EWF and CSWIP Senior Welding Inspector certifications, ensuring compliance with industry standards. We conduct thorough welding inspections, ISO 3834-2 Welding quality management audits and ISO 1090-2 Factory Production control (FPC) Audits, alongside the ability to perform compliance checks to enhance structural integrity and manufacturing efficiency. We can also offer a full suite of system and internal audits to ensure compliance to ISO 9001, 14001 and 45001.

Prior to any welding procedure is implemented, we conduct thorough reviews to ensure compliance with industry codes, project specifications, and client requirements. Our WPS review services include:

- Verification Against Standards– Ensuring WPS aligns with applicable codes (ISO,ASME, AWS, API, EN).

- Assessment of Essential & Non-Essential Variables – Reviewing parameters such as welding position, joint design, filler material, preheat/post-weld heat treatment, and shielding gas selection.

- Comparative Analysis – Checking WPS against approved PQRs to ensure qualification validity.

- Remote Visual Inspection – Using our Inspection robot, in tandem with our UltraHD Camera system and optical zoom

capabilities for enhanced views. We can offer exceptionally detailed visual inspection services undertaking advanced inspection where it is either impossible to assess by humans, or the safety risk is unacceptably high.